Valves are technically fittings, but are usually discussed as a separate category which are used in virtually every industrial process, including water and sewage processing, mining, power generation, processing of oil, gas and petroleum, food manufacturing, chemical and plastic manufacturing and many other fields.

Gronex provides both Cast Iron and Ductile Iron valves to regulate the flow / pressure / air in Cast Iron / Ductile Iron Pipeline systems. These are available with Flange Joints and are connected using Nut Bolts. Valves come in various Standards, Pressure Ratings and Builds. The size starts from as small as 15 mm and goes up to 1000 – 1200 mm.

SLUICE VALVE

The gate which regulates the sluice is a valve known as the sluice valve. These gates are made to be sealed in one direction and are typically used to regulate water levels and flow in streams and canals. Sluice gate valve can also be used in wastewater treatment plants.

Sluice gate valves are commonly used to cut off the liquid flow and cannot be used as a flow regulator. In a completely open position, there is no obstacle in the flow path by the sluice valve, which result in very little flow-resistance. Sluice valves are often used for larger pipe diameters as they have easy and simple construction than other types of large valves.

BUTTERFLY VALVE

Butterfly valves have many benefits over other types of valves, such as economic construction, which consists of fewer components, making it easier to operate and maintain.

Concentric butterfly valves employ soft sealing material due to which it can only be used in basic (water and wastewater treatment plant), special liquid (chemicals, abrasive liquids, etc), and gases for up to 200 psi and 400degree F.

USAGE AREAS

- Water treatment.

- Water Distribution.

- Water Transmission.

- Aeration System.

- Fire Protection, etc.

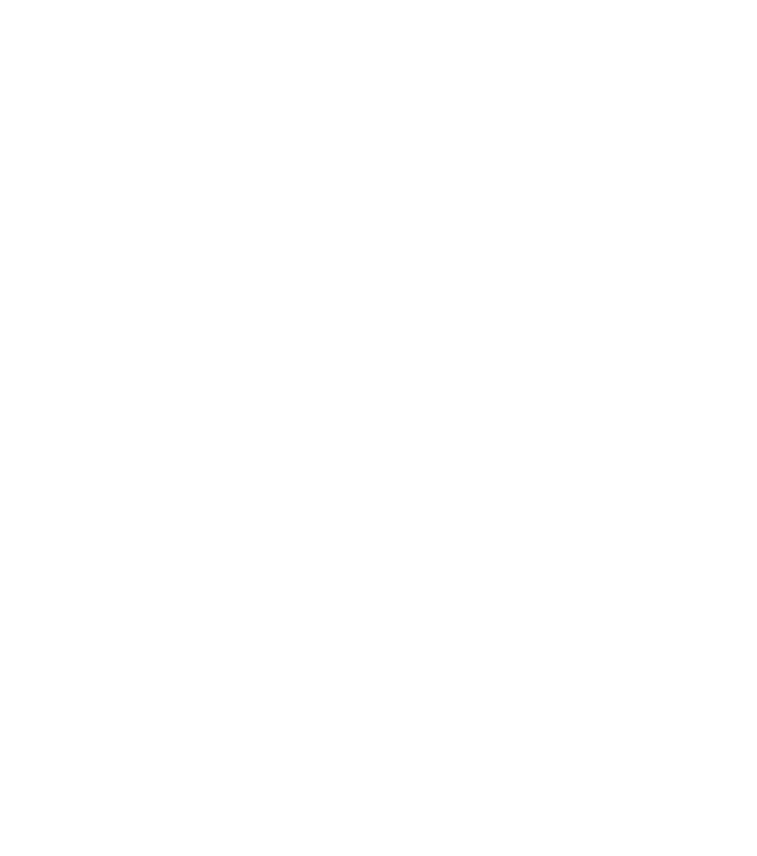

CHECK VALVE

Check valves are also called non return valve, reflux valve, retention valve or one-way valve. This type of industrial valve is automatically opened and closed by the force generated by the flow of the medium itself in the pipeline, which can categorize as an automatic valve.

Check valves are used in pipeline systems, their main functions are to prevent backflow of the medium, to prevent the pump and its drive motor from reversing, and to backflow of the medium from container.

USAGE AREAS

- Water supply system of high-rise buildings.

- Chemical corrosive medium system.

- Water Transmission.

- Sewage system

- Drainage system, etc.

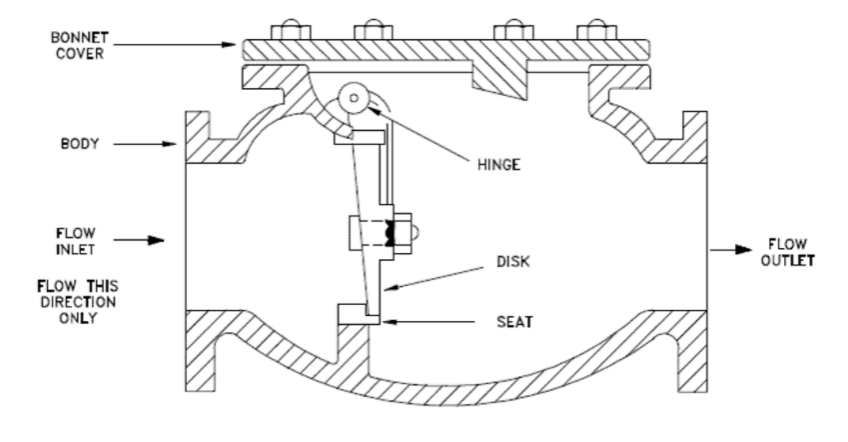

BALL VALVE

Ball valve is mainly used to cut off, distribute and change the direction of medium flow in pipeline. V shaped ball valve opening also has a good flow adjustment function. Ball valve only needs to be operated with a rotation of 90 degrees and a small turning torque to close tightly.

Ball Valve has a simple structure and good sealing performance. It can configure smaller nominal diameter, lightweight, low material consumption, small installation size, small driving torque, simple operation, easy to realize quick opening and closing, and easy operation within a certain nominal passage range and maintenance. The ball valve is suitable for general working media such as water, solvents, acids and natural gas, but also for media with severe working conditions, such as oxygen, hydrogen peroxide, methane and ethylene.

USAGE AREAS

- Oil and natural gas pipelines.

- Metallurgical systems.

- Electric power systems.

- Petrochemical installations.

- High-temperature medium piping systems, etc.

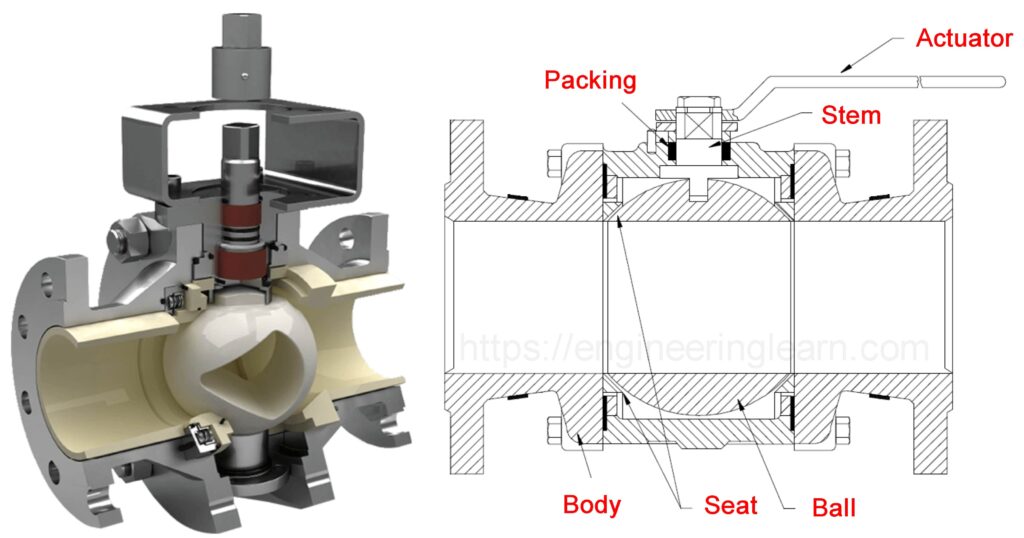

FOOT VALVE

A foot valve is a type of check valve that is typically installed at a pump or at the bottom of a pipe line (hence the name). Foot valves act like ball check valves, but have an open end with a shield or screen over it to block debris from entering the line. The valve opening is designed to be larger than the line itself, minimizing head loss.

Foot valves can be found in ponds, pools and almost anywhere there is a pump. These special valves allow the pump to stay primed, letting liquid to flow in, but keeping it from flowing back out. The screens or baskets that cover the valve opening tend to get clogged over time, especially in ponds and wells. It is important to check and clean your valves regularly for optimum performance.

USAGE AREAS

- Protect pumps.

- Protect Meters.

- Protect control valves.

- Turbines.

- Sensitive Equipents, etc.

AIR VALVE

Air valves are hydromechanical devices designed to automatically release air and wastewater gases or admit air during the filling, draining or operation of liquid piping systems for water and wastewater services.

The safe and efficient operation of a liquid piping system is dependent on the continual removal of air and wastewater gases from the liquid piping system.

USAGE AREAS

- Street underpasses.

- Flow meters.

- Long constant-sloped pipeline segments.

- Turbines.

- Rising mains from pumps to release and admit the air, etc.

STRAINERS

A pipe strainer is a device that serves as a means to remove solids from a flow of the fluid mechanically. Once the strainer is fully attached the fluid flows through the filter housing into the suction segment. When fluid flows, the strainer catches and keeps all foreign materials in place. This can include seaweed, plastics, big particles, etc. Well-functioning strainers successfully block foreign particles.

In pipelines, strainers are used to shield downstream machineries such as condensers, cooling systems, pumps, compressors, meters, spray nozzles, generators, and steam traps from the adverse impact of sediments, corrosion, pipe scales, or other foreign debris.

USAGE AREAS

- Protect pumps.

- Protect Meters.

- Protect control valves.

- Turbines.

- Sensitive Equipents, etc.

FIRE HYDRANT

A fire hydrant is simply a valve-like device similar in function to your water tap that provides constant water flow when you open it. Firefighters connect their water hose to that big valve that provide pressurized water flow (normally at 65 psi) to fight a fire.

To allow easy access for firefighters to extinguish the fire, landing valves are installed on risers of a building, where staircase landings are typically located. For this reason, landing valves can be regarded as all types of valves related to buildings. The landing valve is considered a core part of the hose system that works as a manual stop valve allowing you to completely control your firefighting system. To activate the water flux of the firefighting system, you simply turn the landing valve handle counterclockwise.